Revolutionising Dry Bulk Containerization

SpecialTEUs, a brand within V@RR, is redefining the future of global logistics with what it calls Containerization 3.0. – a smart way to carry pure dry bulk cargoes in containers. Moving beyond traditional standards, SpecialTEUs introduces custom-designed containers created for specific cargoes on specific trades — an approach to reduce imbalances in transport modes currently used, increase intermodal transportation, to optimise supply chains, cut emissions, and ultimately boost profitability & societal gains.

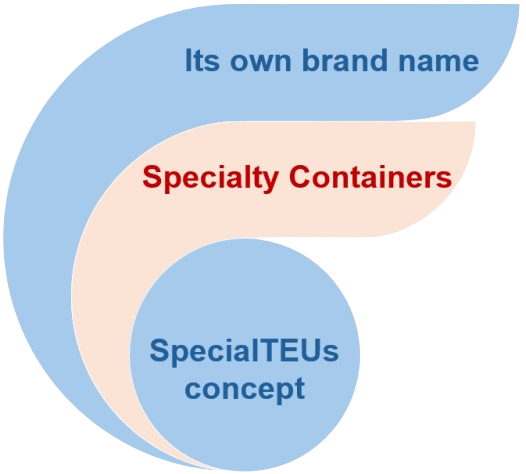

V@RR (Value at Risk) is a Dutch company that develops advanced solutions for financial & strategic risk management across the maritime transportation, intermodal and global logistics sectors. The approach uses in-depth market understanding combined with corporate support function expertise. Where they lack expertise, they collaborate with their network of industry specialists. The company’s SpecialTEUs-concept builds on this foundation by applying system-level thinking to container design — aligning equipment innovation to improve logistics processes with broader sustainability and safety-reduction strategies. V@RR acts a business development & sales agent for its strategic partner that holds the technical know-how of design, certification and manufacturing of the containers.

From standardisation to specialisation

The first container revolution was built on standardisation. It created global interoperability, improved handling speed and enabled seamless intermodal transport. Today, new trends provide opportunities and challenges which are reshaping the landscape. Trends include port congestion, space scarcity & autonomous systems in ports, changes in manufacturing processes, altering commodity scarcity, increased need for granularity, rising ESG pressures and stricter safety regulations

SpecialTEUs responds to these macro trends by tailoring container design to match the exact needs of shippers. Rather than transporting “air”, the new model maximises capacity and reduces waste, directly contributing to lower emissions and higher operational efficiency.

Tailored for dry bulk and beyond

At the heart of the concept lies a focus on dry bulk cargoes: agricultural products, forestry goods, steel, polymers, mining output and construction materials. These specialty containers are often deployed on dedicated trades, ensuring they return efficiently to their point of origin either by carrying a return cargo that suits destination and box design or in foldable form (typically 1:4 or 1:5 ratio).

The approach further addresses many risks associated with using standard containers for dry bulk cargoes, including unsafe loading, overweight cargo, contamination, and structural failures. By designing each unit around the specific characteristics of its cargo, SpecialTEUs improves safety, consistency, and regulatory compliance.

Smarter, greener, and more connected

Each box can include IoT tracking, inside liners and foldable or multi-cargo features to optimise fleet use. They are fully maritime-certified and designed through a “full logistic chain” perspective. The result, says V@RR, is not just getting a container, but buying a logistics solution. A thorough modular approach is used covering operational assessment, design, certification, manufacturing, training, and trial testing. This approach covers potential first concerns on cost, compatibility, box functionality and handling complexity in a step-by-step fashion. The payoff is clear: greater flexibility, higher safety, lower emissions, and stronger bottom-line results.

Railfreight November 2025